A painstaking process but well worth my while. Identifying the problem was easy and the repair itself was simple. What used to be a piece of junk, lo and behold, shines once again.

Some stickers were just too stubborn to go away so a couple of cleaning chemicals were tried-out, all of which were tolerated well by the surfaces. The rubbery side panels ended-up being washed with warm water and dish detergent, after trying all mild alcohol solutions. One that did not take well the washing was the meter switch knob, which apparently was made of some sort of bakelite that kept bleeding out a black substance leaving a the knob all spongy. I stopped immediately, dried the piece, soaked it in an vegetal oil then gave it a good polish using a piece of cloth. To my surprise, all the crevices disappeared but the surface was not as smooth as of the others. This could have been yet another design feature, as this knob needs quite a bit of torque to be switched through positions. Maybe, the engineers considered plastic too slippery for the job.

Another piece that was handled extra-carefully was the meter. First, it needed to come off and that was a challenge in itself as it's kept in place by a fragile piece of plastic. In fact, that piece is the only design flaw I could find and as far as I observe, it is Achille's heel for other HP power supply models. This black bezel relies on its elasticity to hold the meter onto the metal face. To be elastic it has to be thin but at the same time it can easily break under the meter's weight on a moderate shock. Mine was cracked but not broken, likely during delivery, thus the extra-care I mentioned earlier. So, the meter was gently washed just with a very dump piece of paper. No solutions were used and luckily all the dirt and gunk went away eventually, leaving a rather smooth surface. Because some scratches were beginning to show, I chose once again to use an oil-based coating followed by a gentle karate-kid polishing at the end.

Since its reinstatement some months ago, the unit has been put to work, mostly for charging battery packs and often for powering test circuits. Nothing overheated or broke even when I short-circuited it with the current setting to max. In the latter case, the ballast resistor correctly took over all the dissipation.

Adaptation

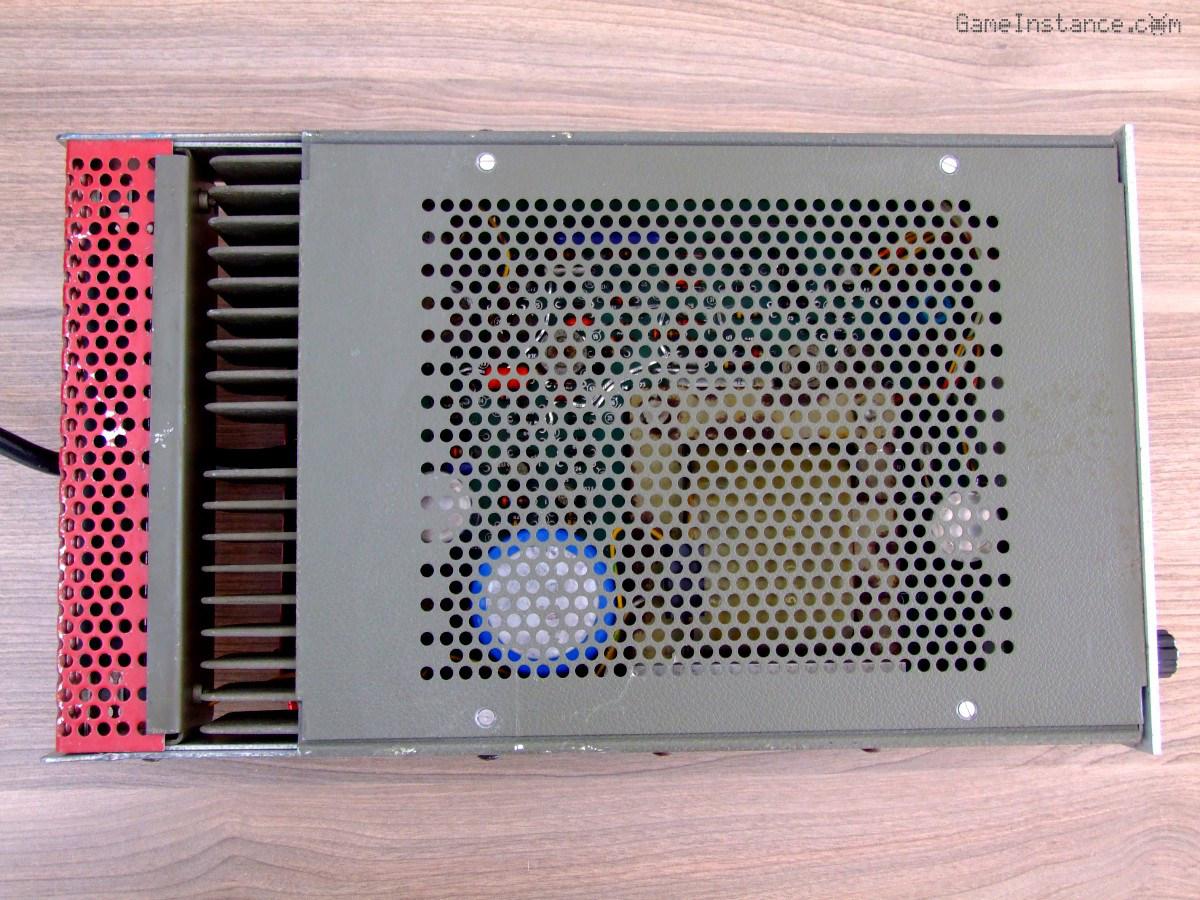

The unit looks good and works perfectly, event after 50 years. It was not designed to be used on a desk as it doesn't have any contact feet to protect the surfaces, prevent slipping or allow tilting. To cope with that, I've added self-sticking furniture pads to the under-side of the unit: two 4cm high rubber ones in the front and two 0.5cm felt ones at the back. This gave just enough angle to see the meter and a decent surface grip. The fact that the indicator isn't illuminated was a bit of a problem but I refrained from modding it further more as I like it the way it was designed.

That said, I do find annoying the "warm-up time" needed by the pair of transistors handling the movement indicator. Also, its rotary switch is imperfect at times but that can be fixed with yet more contact cleaning sprayed onto the switch.

All in all, this is a simple, yet reliable unit and with a cap replacement every now in a decade, will keep working for generations.